Today’s market trend has been profoundly marked by the arrival of Industry 4.0: the growing and constant demand for products in ever-increasing quantities, but with extremely high-quality levels, has led companies to realise how necessary it really is to adapt production to the new market standards.

This fourth industrial revolution requires companies to intensify their production activities. It is essential to optimise time and costs of production process while respecting available resources. Therefore, industrial robotic automation has become the protagonist of change 4.0: its ability to reproduce human work in detail, guaranteeing identical results that can be repeated over time, makes possible not only to increase daily production, but also to relieve operators of strenuous or unrewarding tasks. The robot’s ability to perform tasks that are risky for humans, such as cutting or finishing surfaces, improves safety levels within the company and reduces the risk of injury.

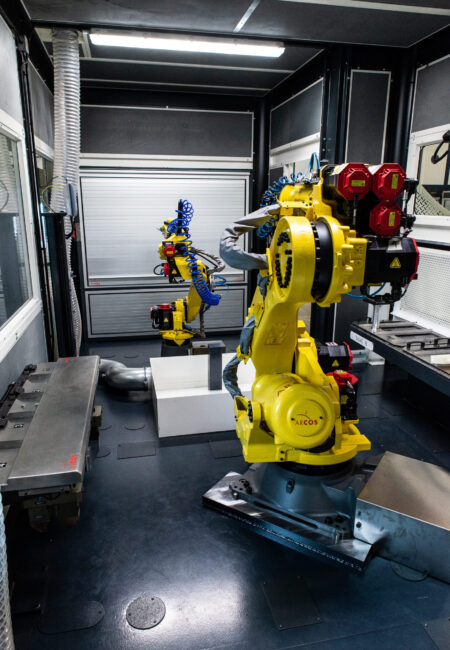

In this article, Arcos introduces one of its robotic finishing technologies, robot cells, and some of the automated systems it has designed to enable companies to optimise productivity, increase safety and outperform the competition.

Table of Contents

Robotized cells according to Arcos

Thanks to the important progress made in the scope of automation, it is now possible to have innovative technologies that allow you to improve the production flow of your company and, consequently, to remain competitive within the new markets with ever-increasing technological content.

Arcos is aware that this change is going to increase and wants to offer all its expertise in automated finishing processes to provide its customers with the best integration systems.

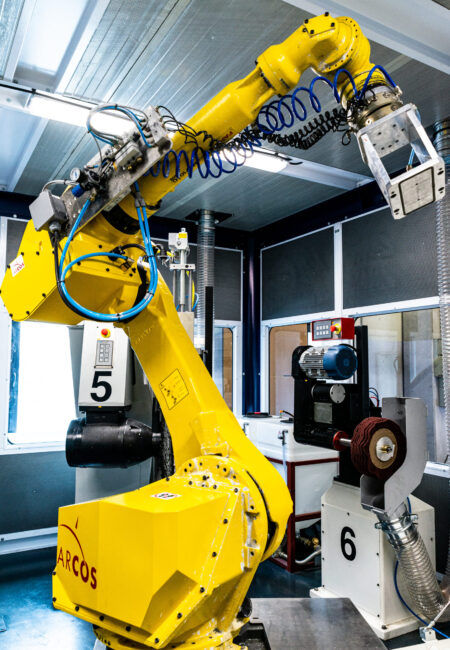

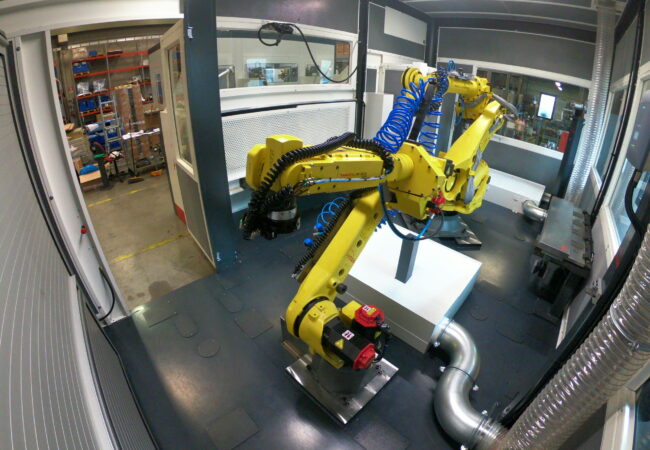

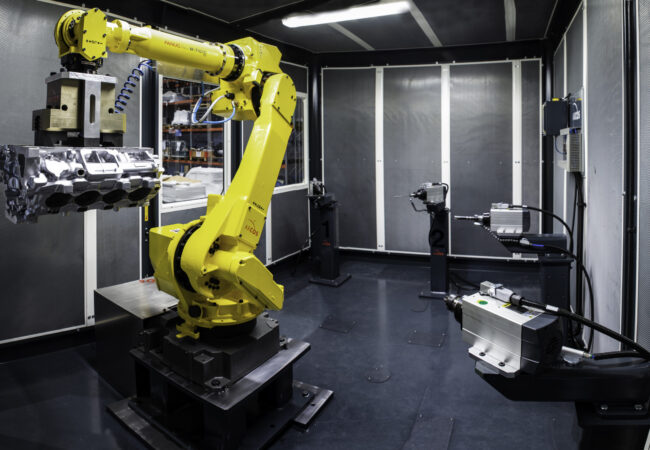

Among surface finishing technologies, robot cells represent the most versatile and customisable solution for those realities with high production activity. Depending on requirements, the automatic work cells can be fitted with: one or more programmable robots, rotary tables for manual loading/unloading of workpieces or conveyor belts for automatic transport, alternative work centres with multi-function robots, washing or drilling units and any other necessary element specifically designed and created for the required machining operation.

In fact, Arcos robotic cells are created to satisfy all industrial automation standards and adapt to the production requirements of each sector, but, above all, to maximise, speed up and simplify a complete production module and achieve high levels of product quality repeatability.

The tasks performed by each robotic cell are characterised by short cycle times and a low margin for error, resulting in lower costs and a real increase in the quality of the finished product.

In addition, thanks to the programmability of Arcos robots, it is possible to use the robotic cell flexibly and adapt it quickly to production changes without making any modifications: all that is needed is to change the operation required to the cell to proceed with the new production processes.

Arcos robotic cells are also equipped with a system of collection, storage and administration of production data for a more intelligent machine management. In fact, thanks to the direct connection with the company’s management software, there will be continuous and constant communication with the company’s databases, thus preventing data from being lost. This software is usually supported by routers, allowing remote control of the robotic cell or the resolution of any problems.

The in-depth knowledge of safety needs and requirements developed by Arcos over many years of experience enables the company to tailor technologies to suit every need. This ability has enabled many sectors, including the aeronautical and aerospace one or automotive industries, to improve their production process through the installation of automation machines capable of meeting the highest demands.

Indeed, this type of robotic automation can be used in any industrial sector (fashion and luxury, medical, aeronautics, mechanics, furniture and design, food, etc.) and, whatever the task performed by a robotic cell is, the output will be precise and reliable.

Automating the production process for the health of operators

The installation of robotic automation within the company also plays a fundamental role in creating a safer and more stimulating environment for operating staff. In fact, the risks for workers can be many: accident risks, such as injuries or crushing caused by handling workpieces and falls; injuries due to the use of particularly dangerous or sharp tools; occupational diseases caused by repetitive tasks; respiratory diseases due to the dispersion of dust during work and diseases caused by tool vibration.

Robotic cells therefore contribute to a safer and more reliable working environment: the operator is relieved from carrying out dangerous or high-risk production processes himself but will perform tasks in support of the cell. In this way, those tasks defined as alienating and risky will be replaced by jobs with a higher level of staff involvement. The operators will be trained by Arcos experts to learn how to program the robot cells assigned to them, abandoning manual tasks definitively.

Safety is not only offered in the transition from manual to automated work, but also in the safety systems installed in the Arcos robotic cells: each cell has soundproofed, aspirated protection cabins and an HMI (Human Machine Interface) supervision system that allows the work of the machine to be monitored through displays, control panels and computers.

Conclusion

Thanks to robot cells, a new era has begun for the industrial sector and its operators: these robotized systems are characterised by a very high level of autonomy that allows night and holiday shifts to be covered even without the intervention of operators, guaranteeing longer production times, maximising production levels and ensuring a shorter cycle time, while maintaining high quality standards. In addition, the inclusion of automated cells in the production chain ensures a higher level of safety at work, allowing staff to limit the risk of injury due to repetitive or dangerous tasks.

Aware of the impact that the industrial revolution has on the enterprises’ workforce, Arcos offers a support service for robotic systems and all-round training calibrated to the operators’ technical knowledge to ensure excellent results from the use of Arcos automatic systems.

Thanks to the collaboration between engineers, experts and customers, Arcos studies and develops customised robotic cells for every need. The reliability, versatility and customisation that characterise Arcos systems make them the best answer to every finishing problem and production need.

If you want to be part of Industry 4.0 too, do not hesitate to contact us: the Arcos team will be on hand to answer any questions you may have.