AUTOMATED

ROBOTIC SANDING SYSTEMS

What is it

Robotic Sanding

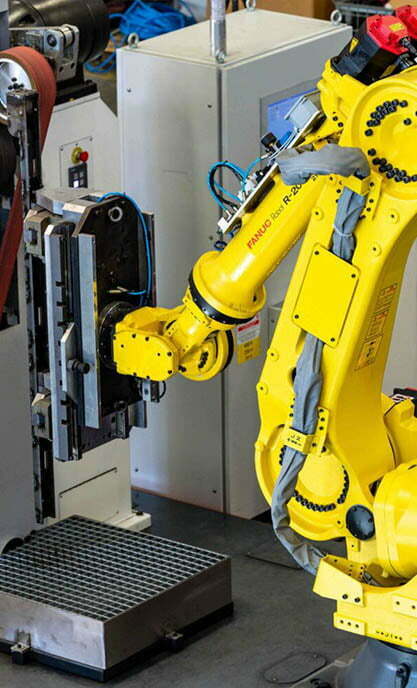

Automated sanding uses state-of-the-art robotic systems equipped with abrasive tools to smooth and polish surfaces with incredible precision. This cutting-edge technology is a game-changer in industries like automotive, aerospace, and furniture manufacturing. Why? Because it ensures surfaces are perfectly prepared for further treatments like painting or coating, ensuring that the final product is flawless and durable.

The process involves a robotic arm meticulously guiding the sanding tool over surfaces, following precise paths to achieve a flawless finish.

The benefits are tangible: boosted efficiency, lower labor costs, and unmatched quality. Plus, these robots can safely operate in environments that are hazardous to humans, enhancing workplace safety.

Discover how this revolutionary technology can transform your operations by watching our in-depth video.

Flawless and uniform surface finish

One of the standout benefits of using robots for automated sanding is their unmatched precision and consistency. Unlike manual sanding, these robotic systems follow exact specifications and maintain exact pressure and speed throughout the sanding process, eliminating variations caused by human fatigue or error. This precision not only minimizes material waste but also ensures every product meets the highest quality standards.

This precision is especially critical in applications requiring tight tolerances, such as preparing aircraft components or automotive body panels for painting, where even minor inconsistencies can lead to defects or rework.

Contact us and discover how our robotic solutions can enhance precision and consistency.

Cut cycle times and enhance productivity

Implementing robots for automated sanding leads to a significant boost in efficiency and productivity. Unlike human workers, these robots can operate in continuous production cycles without downtime and fatigue, resulting in higher throughput and reduced cycle times. They perform repetitive tasks with speed and accuracy, drastically cutting down production time.

By integrating robotic sanding systems, companies can free up human resources for more complex tasks, optimizing their workforce. This efficiency boost not only enhances production capabilities but also leads to substantial cost savings.

Learn how our robotic solutions can elevate your operational efficiency: contact us today.

robotic sanding

Case studies for sanding

Robotic system for the grinding of taps

This robotic system is designed to automate the tap grinding process. It has great elasticity thanks to the two triple grinder units and the pliers designed to reproduce all human movements.

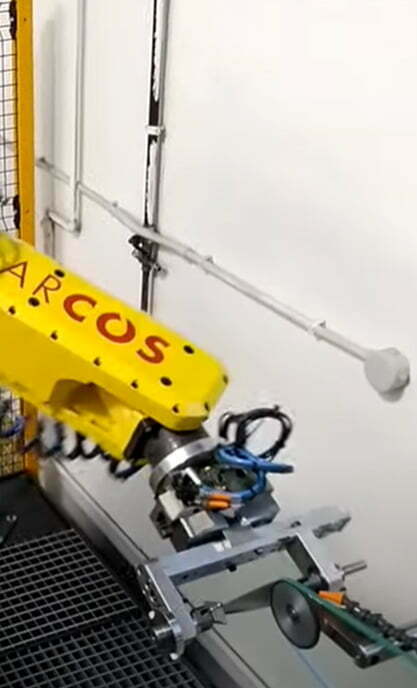

...Robotic system for grinding metal components for loading systems guides

The robotic system is designed to ensure the grinding of metal components for of load system guides. The robot guarantees the right versatility to work pieces of different sizes and lengths.

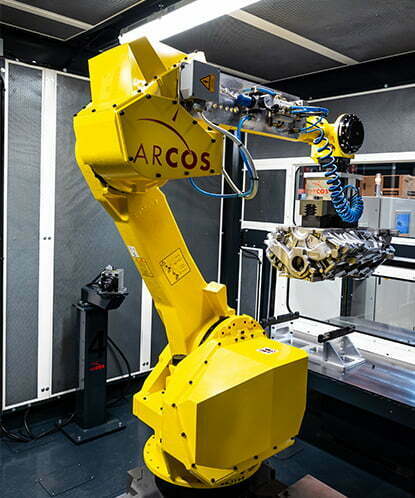

...Robotic system for precision grinding of aeronautical parts

Robotic system for precision grinding of aeronautical parts through a test system and calculation of the work program.

...Features

ARCOS MACHINES

Recommended machines for sanding

ROBOTISED SYSTEMS

Robotic work cells for surface finishing. Polishing, deburring and much more: Perfect for literally any material. The extreme simplicity of use and versatility have made robotic systems the best answer for every finishing problem.

CONTINUOUS ROTARY TABLES

Continuous revolving tables for polishing. An ideal solution in the case of production of many pieces, with simple and symmetrical shapes like rosettes, cylinders, knobs, handles etc.

INDEXED-CNC ROTARY TABLES

Snapping rotary table and CNC for polishing . Ideal machine for large quantities and for processing of pots, cookware, flat buckles, lids etc. With the introduction of CNC it is possible to combine high productivity even with medium-complex pieces.

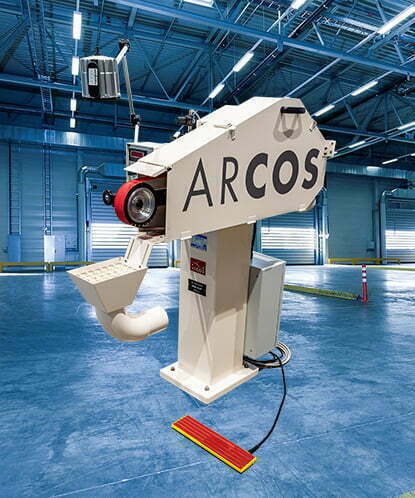

MANUAL MACHINES

Arcos manual machines for satin finishing of metal. Cleaning machines, polishing machines and manual grinders set at two speeds with or with an inverter, these are equipped with full safety control systems.

CENTERLESS MACHINES

Centreless machines for polishing and grinding. Ideal solutions for surface finishing of tubes or circular section bars.

FLAT SURFACE MACHINES

Flat machines for polishing and grinding. Ideal solutions for surface finishing of slabs or flat elements of varying width and length.

robotic sanding

Type of materials

Cast iron

Glass

Aluminum alloys

Brass

Zamak

Hard stones

Inconel®

Magnesium alloys

Composite materials

Plastic

Steel/Stainless steel

Titanium alloys

robotic sanding

Types of objects

- Turbine blades (energy and aeronautics)

- Airborne engine components

- Blisk

- Welding

- Castings processes

- Weapons

- Components for the automotive sector

- Taps

- Bathroom accessories

- Medical implants

- Handles for doors and windows

- Fashion accessories

- Furnishing accessories

- Kitchen utensils

- Pots and cutlery

DEBURRING DISCOVER MORE

GRINDING, SANDING, LINISHING DISCOVER MORE

BUFFING AND POLISHING DISCOVER MORE

SANDBLASTING DISCOVER MORE

SATIN FINISHING DISCOVER MORE

CUTTING SYSTEMS DISCOVER MORE

CONTACT US