Industrial sandblasting robots

What is it

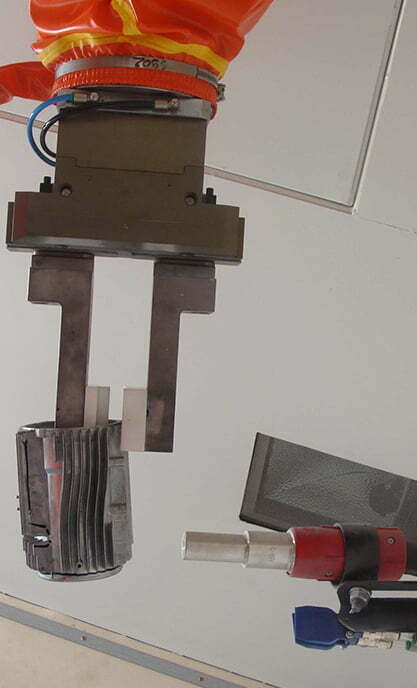

Robotic sandblasting

Sandblasting is a mechanical metal cleaning process which consists in the removal of the first surface layer of the material. The applied technology exploit the mechanical action of a air jet of abrasive material.

Consistent quality and precision

Robots bring a new level of precision and consistency to sandblasting, eliminating the issues of uneven surfaces or quality variations often seen with manual methods.

In sectors like aerospace, automotive, and manufacturing, where surface quality is paramount, robotic sandblasting ensures surfaces are prepared to the highest standards every time. The result? Better adhesion of coatings, fewer reworks, and more durable products.

By investing in robotic sandblasting, companies can guarantee a superior finish that translates into high-quality output and long-term cost savings.

ROI improvement

Robotic sandblasting consistently delivers uniform surface quality, minimizing the risk of defects or missed areas that would require rework. With fewer mistakes, companies can save both time and money by reducing the need to repeat the process.

This approach also lowers material waste, including coatings and abrasives, while cutting down on labor costs. The result is increased efficiency across the board and significant cost savings for your operation.

ROBOTIC SANDBLASTING

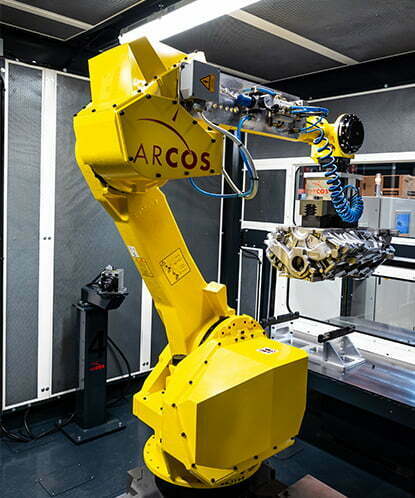

Case study for robotic sandblasting

ARCOS MACHINES

Recommended machines for robotic sandblasting

ROBOTIC SANDBLASTING

Type of materials

Cast iron

Glass

Aluminum alloys

Brass

Zamak

Hard stones

Inconel®

Magnesium alloys

Composite materials

Plastic

Steel/Stainless steel

Titanium alloys

ROBOTIC SANDBLASTING

Types of objects

CONTACT US