What is it

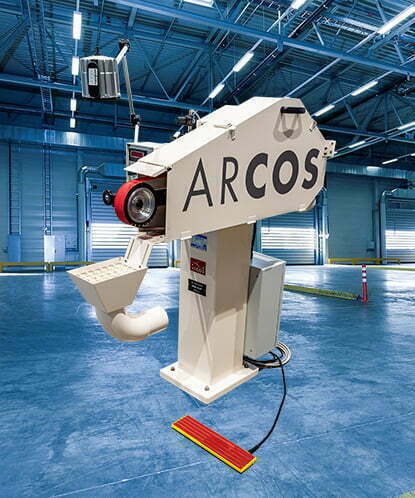

Metal Buffing and Polishing Machines

The polishing process can have a dual purpose:

for components requiring polished surfaces solely for their reflective and polished appearance. Components of this type are accessories for furniture, aesthetics elements for automotive and much more.

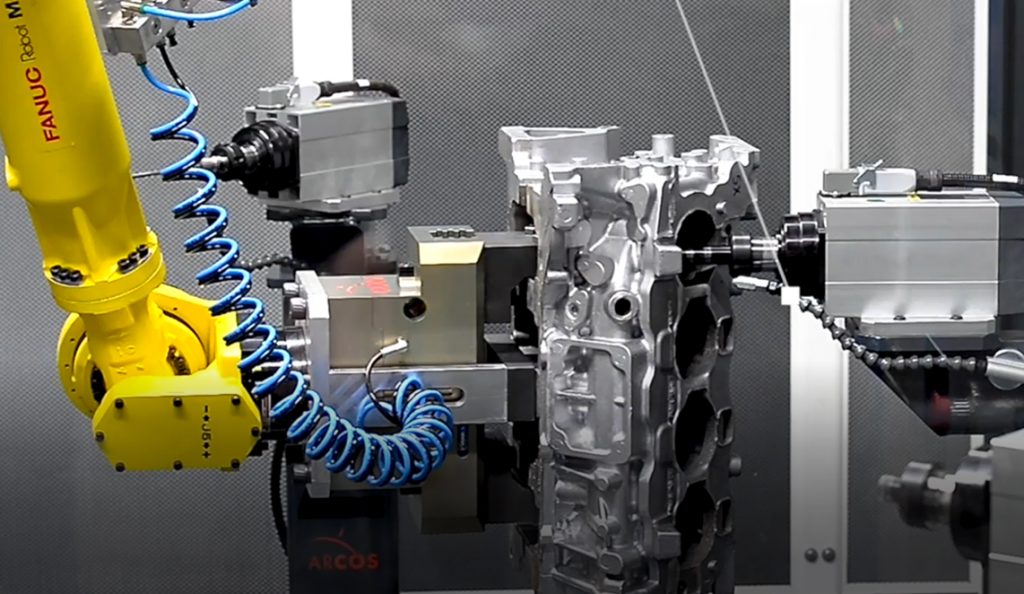

dedicated to those components that due to their mechanical application require extremely reduced roughness. In this case polishing is required by their function. Typical examples are found in components for automotive.

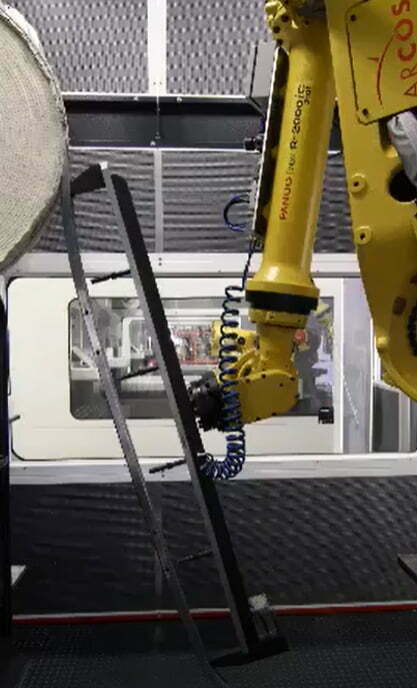

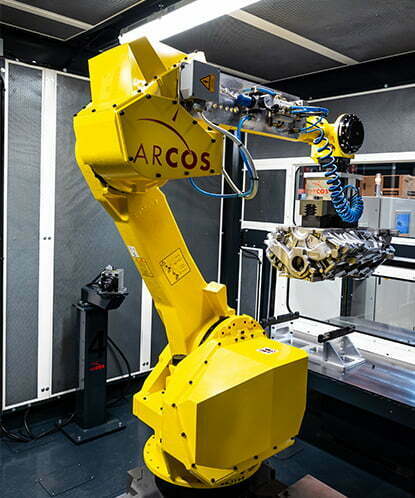

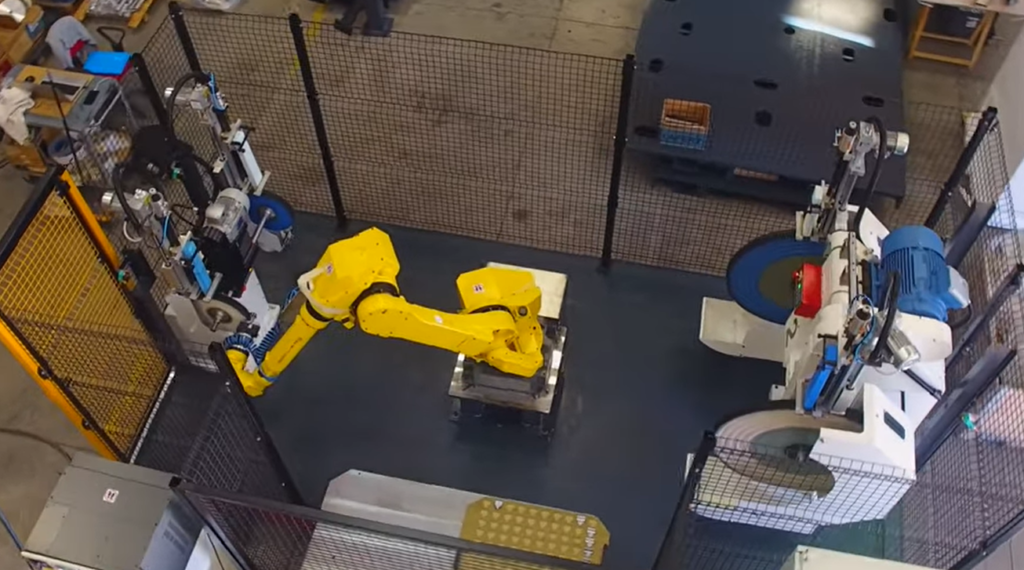

Automated robotic buffing machines

Eliminate costly post processing retouches

Consistent quality, even on different shapes

Type of processing

polishing and finishing

Case studies for polishing/buffing/brightening

ARCOS MACHINES

Recommended machines for polishing/buffing/brightening

polishing and finishing

Type of materials

Cast iron

Glass

Aluminum alloys

Brass

Zamak

Hard stones

Inconel®

Magnesium alloys

Composite materials

Plastic

Steel/Stainless steel

Titanium alloys

polishing and finishing

Types of objects

CONTACT US