The fields that make, use or sell products with metal parts know of the decisive role played by material finishing processes in order to achieve the finished object.

Metal grinding is one of the key steps to refine the surface of objects and make them consonant with their intended use, so that they are perfectly matched and safe.

How does this process work and what are the most innovative ways to introduce it within your company? Find out in this in-depth discussion, with some concrete examples of Arcos technology at work.

Table of Contents

What is meant by metal grinding?

Metal grinding involves the removal of excess material from workpieces through the use of abrasive material. Superfluous parts are removed from the object so that subsequent treatments, when necessary, can be carried out and to give the object the correct size required.

The abrasive material used allows the object to go through different stages of grit: from the coarsest, to intermediate, to the finest grit. The abrasive materials useful for carrying out this work are many; mainly, abrasive belts (cloth or paper) cloth flap wheels or discs can be used.

Depending on the destination of the object and the purpose for which it is being processed, grinding can be the concluding finishing process or be preparatory to subsequent ones for an even more detailed finish.

What metals is it possible to grind?

The metals on which grinding is usually carried out are steel, titanium and aluminum alloy, cast iron, and brass. Inconel, magnesium alloys, and zamak are also perfectly processed.

What is the best tool to carry out metal grinding?

There are many tools on the market for carrying out metal grinding. You should choose the one that best suits your production needs based on the type of metal to be processed, the size and shape of the object, and the quantity of parts to be processed.

The most innovative technologies available on the market today are:

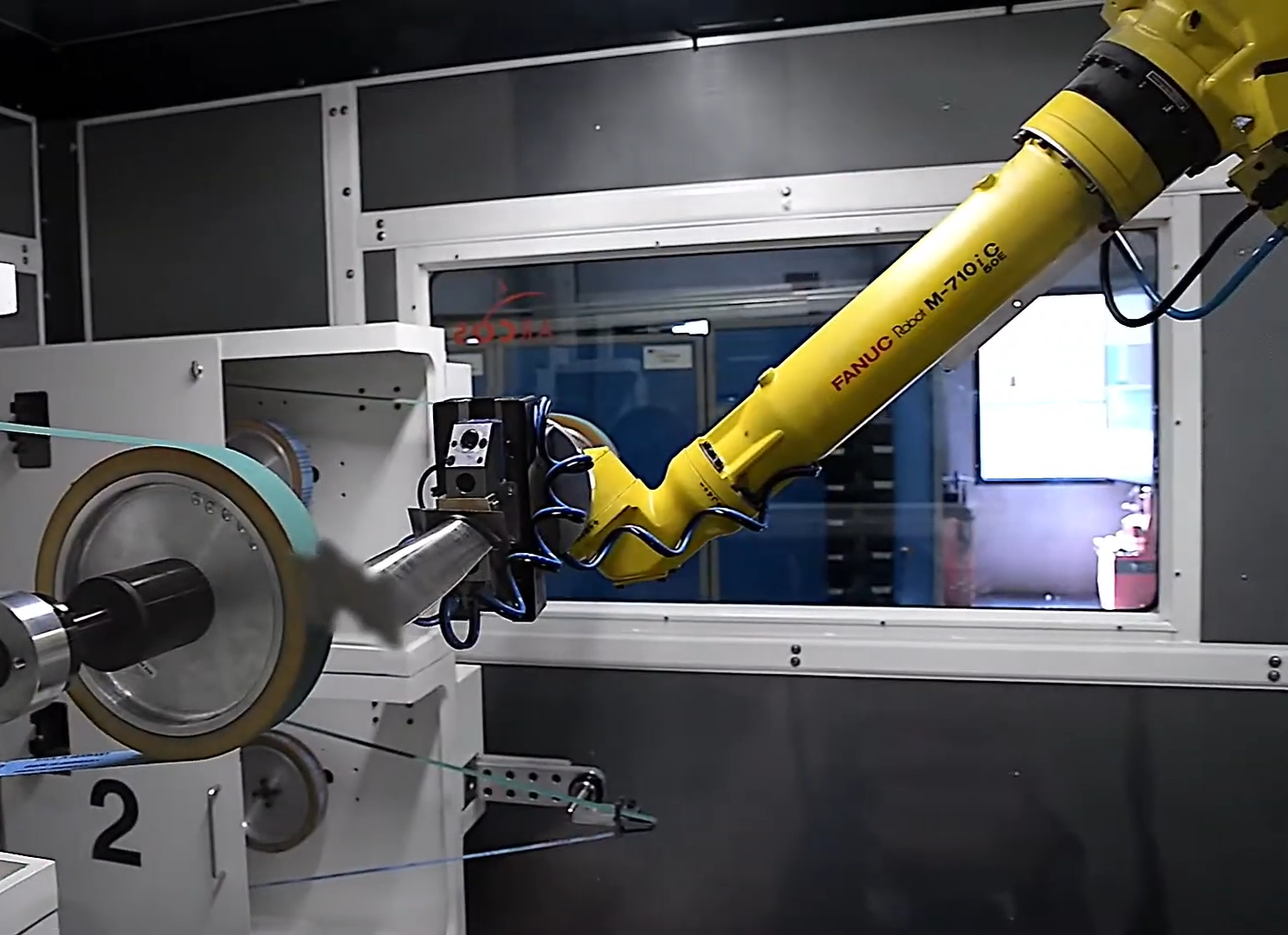

- Robotic systems. User-friendly, versatile technologies and highly customizable for your production reality.

- Continuous rotary table. Perfect solution in the presence of the production of a very large number of parts.

- Indexed-CNC rotary tables. For reduced production of parts.

- Centerless machine. Especially recommended for finishing tubes or bars with circular cross-section.

- Flat surface machine. Designed to be exploited with plates or flat elements of different sizes in width or length.

- Manual machine. A solution that involves active operator intervention. It has two main speeds and a control system for safety.

The benefits of advanced metal grinding

Of all the useful methods and tools for performing grinding, there is no doubt that automated sanding has unparalleled advantages. Over the years, robotics has made great strides in developing increasingly autonomous, fast, safe and accurate technologies to be incorporated into corporate production systems.

In fact, this processing entrusted to basic technology or the manual dexterity of an operator requires dilated work times, slowed production of finished parts, and continuous exposure to hazards for the worker in charge of finishing. Introducing robotic grinding within one’s production process means guaranteeing a very high level of quality, in which outputs increase and the required work time is reduced. In this context, the operator will only have to program the machines and check that the grinding takes place according to the set process.

More and more companies, even those in extremely sensitive fields with high quality standards, are choosing technologies for medical, aerospace or furniture grinding.

Arcos, alongside innovation for years

The role Arcos has been taking on for years is as an expert consultant and manufacturer of robotic systems for surface finishing, including metal grinding.

Each reality presents different spaces, costs and needs that deserve to be fulfilled with the solution best suited to simplify the machining process, and capable of thus also making production more efficient.

Concrete examples of metal grinding

Here are some concrete examples where it is possible to observe systems completed and customized by Arcos, based on the precise request of the recipient company.

For the grinding of faucets, this robotic system consisting of two triple grinder units was provided, with a customized gripper capable of reproducing all human movements.

Here you can see the grinding of metal components for load system guides in different sizes and lengths.

Finally, this robotic system made for grinding aluminum parts, intended for the aerospace industry. Aerospace turbine blades blanks with different twists are machined with ease.

To see more examples, here you can find plenty of examples of robotic surface finishing systems made by Arcos over the years for a multitude of areas and uses.

In conclusion

The metal grinding systems on the market today are varied: depending on the level of autonomy you wish to have and the type of object to be processed, it is a good idea to evaluate the main solutions available. Today, robotic systems are the most advanced technology to carry out this finishing process, which can be accessed in a customized way thanks to the intervention of Arcos technicians.

Increase production and reduce working time and waste thanks to the metal grinding systems developed by Arcos: for any tomorrow, you can contact us here.