ROBOTIC

GRINDING

What is it

Robotic Grinding

Usually grinding is the preparatory operation to subsequent surface treatments. Grinding means improving the surface through a series of abrasive material passages in a sequence of grits, going from big grits (P24-P32-P60-P80-P100), intermediate grits (P120-P150-P180-P220) up to thin grits (P320-P400-P600).

The workpiece, once it has undergone the frosting treatment, may be finished or may undergo subsequent treatments such as polishing.

Types of processing

The tools used for grinding are:

- Abrasive tapes in canvas

- Abrasive tapes in paper

- Lamellar wheels in canvas

- Discs or wheels

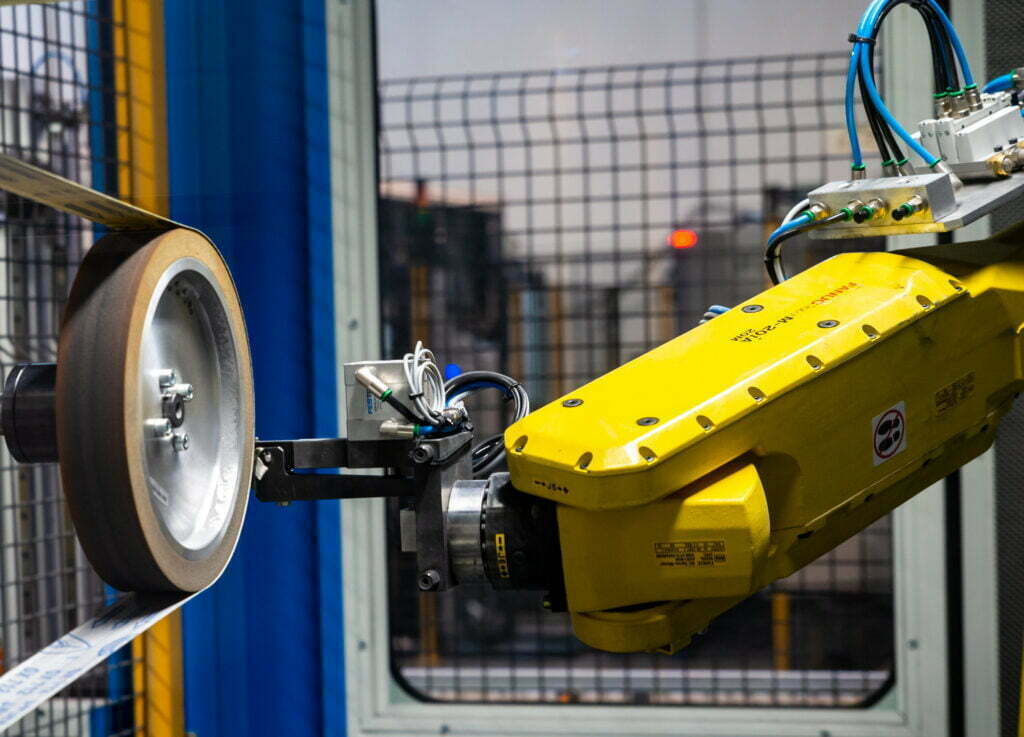

In belt grinding it is very important to choose the contact wheel. The combination of contact wheels with the right abrasive belt allows to obtain the best result.

There are multiple contact wheels:

- Vulkollan® wheels

- Vulkollan® wheels and sponge

- Neoprene wheels

- Smooth and grooved rubber wheels

GRINDING

Study cases for grinding

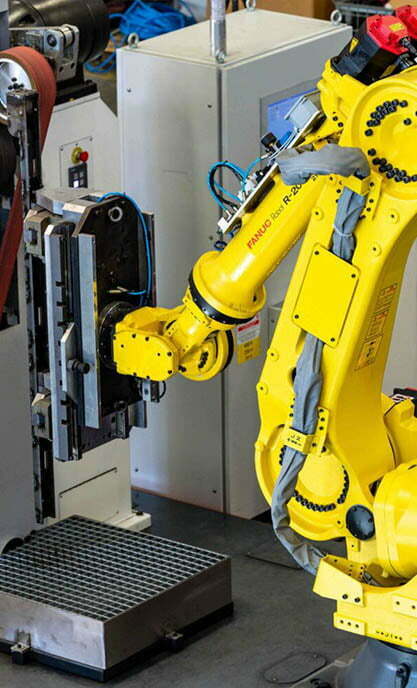

Robotic system for grinding and finishing aluminum parts for the aerospace sector

The Robotized System allows the automatic grinding and finishing of aluminum parts in post processing, starting from rough blades for aerospace turbines that have different torsions

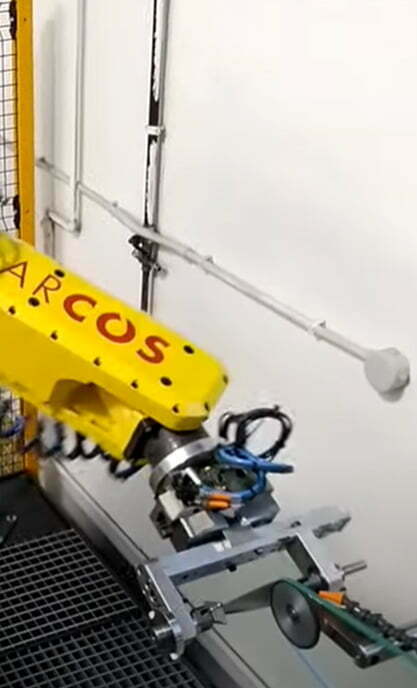

...Robotic system for the grinding of taps

This robotic system is designed to automate the tap grinding process. It has great elasticity thanks to the two triple grinder units and the pliers designed to reproduce all human movements.

...Robotic system for grinding metal components for loading systems guides

The robotic system is designed to ensure the grinding of metal components for of load system guides. The robot guarantees the right versatility to work pieces of different sizes and lengths.

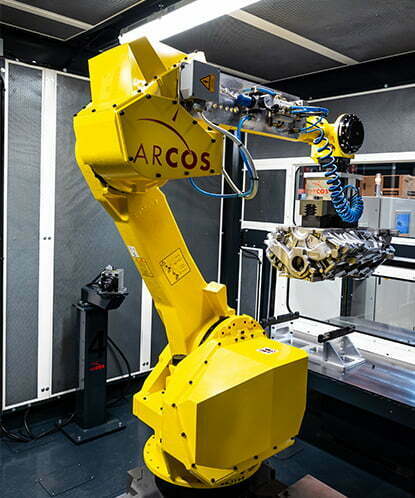

...Robotic system for precision grinding of aeronautical parts

Robotic system for precision grinding of aeronautical parts through a test system and calculation of the work program.

...Features

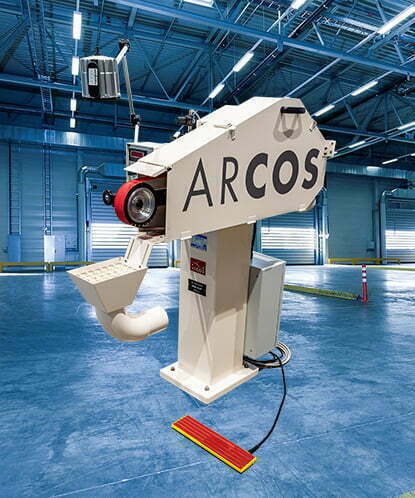

ARCOS MACHINES

Recommended machines for grinding

ROBOTISED SYSTEMS

Robotic work cells for surface finishing. Polishing, deburring and much more: Perfect for literally any material. The extreme simplicity of use and versatility have made robotic systems the best answer for every finishing problem.

CONTINUOUS ROTARY TABLES

Continuous revolving tables for polishing. An ideal solution in the case of production of many pieces, with simple and symmetrical shapes like rosettes, cylinders, knobs, handles etc.

INDEXED-CNC ROTARY TABLES

Snapping rotary table and CNC for polishing . Ideal machine for large quantities and for processing of pots, cookware, flat buckles, lids etc. With the introduction of CNC it is possible to combine high productivity even with medium-complex pieces.

MANUAL MACHINES

Arcos manual machines for satin finishing of metal. Cleaning machines, polishing machines and manual grinders set at two speeds with or with an inverter, these are equipped with full safety control systems.

CENTERLESS MACHINES

Centreless machines for polishing and grinding. Ideal solutions for surface finishing of tubes or circular section bars.

FLAT SURFACE MACHINES

Flat machines for polishing and grinding. Ideal solutions for surface finishing of slabs or flat elements of varying width and length.

GRINDING AND SANDING

Type of materials

Cast iron

Glass

Aluminum alloys

Brass

Zamak

Hard stones

Inconel®

Magnesium alloys

Composite materials

Plastic

Steel/Stainless steel

Titanium alloys

GRINDING AND SANDING

Type of objects

- Turbine blades (energy and aeronautics)

- Airborne engine components

- Blisk

- Welding

- Castings processes

- Weapons

- Components for the automotive sector

- Taps

- Bathroom accessories

- Medical implants

- Handles for doors and windows

- Fashion accessories

- Furnishing accessories

- Kitchen utensils

- Pots and cutlery

DEBURRING DISCOVER MORE

GRINDING, SANDING, LINISHING DISCOVER MORE

BUFFING AND POLISHING DISCOVER MORE

SANDBLASTING DISCOVER MORE

SATIN FINISHING DISCOVER MORE

CUTTING SYSTEMS DISCOVER MORE

CONTACT US