Arcos is able to provide cutting-edge automated solutions for deburring and precision deburring processes, designed to adapt to the geometry and material of the component.

Deburring is a surface finishing process that removes defects (burrs) resulting from manufacturing processes. It is typically the first step before grinding and polishing.

Deburring can be categorized into two main types:

Focuses on removing burrs from parts that don’t have specific functional requirements but need to meet aesthetic standards. This is common in industries such as furniture, fashion, luxury accessories, and similar sectors.

Involves removing burrs from components that have precise functional requirements. This process demands careful selection of tools and methods, and is critical in sectors like automotive, aeronautics, and aerospace, where strict tolerances are necessary.

This is a specific deburring process that involves immersing the component in rotating diamond powder. This process is suitable for deburring hard metal tools.

Flawless finishing and consistent quality

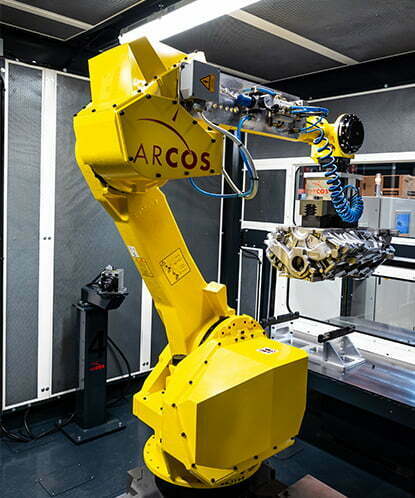

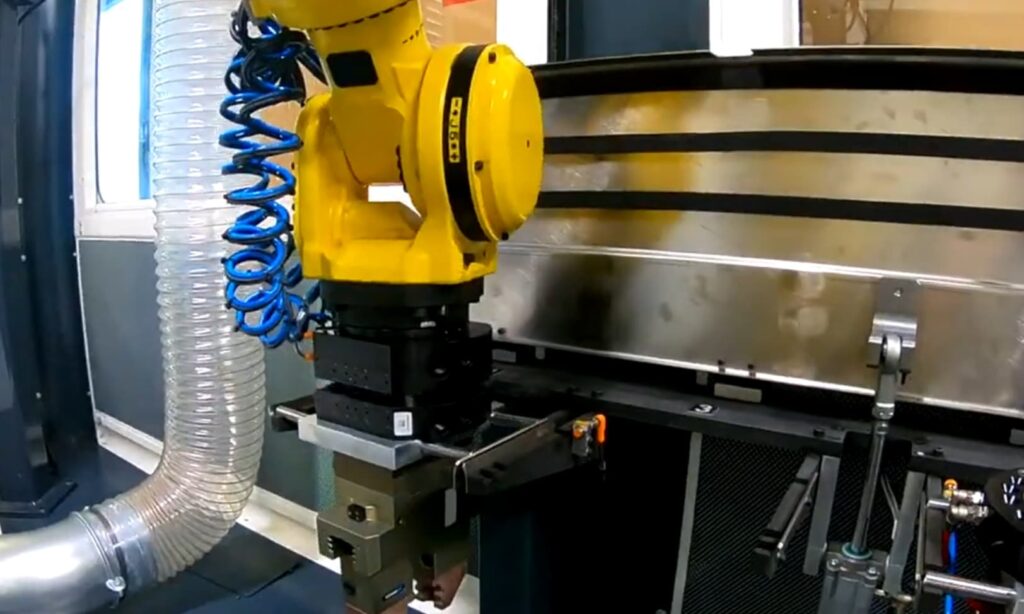

A top-tier finish is defined by its smooth, uniform surface, free from burrs, scratches, or irregularities. Robots, with their advanced sensors and control systems, are specifically designed to deliver this quality consistently across all parts in a batch.

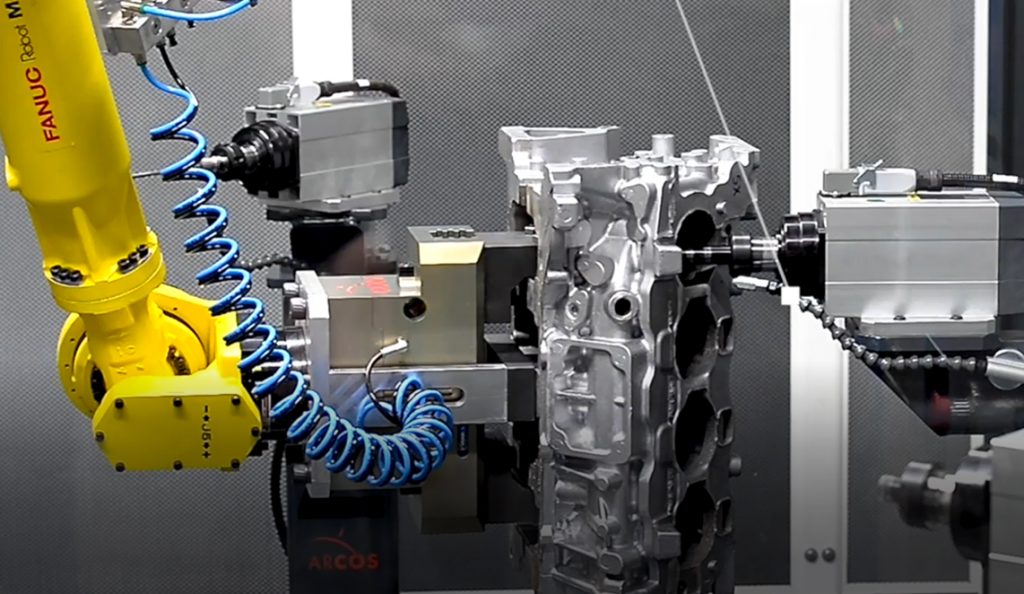

These machines can be programmed to apply the exact amount of pressure needed to remove burrs without damaging the surrounding material. Their ability to handle complex shapes and intricate geometries, while performing repetitive movements with high accuracy, ensures that even the most challenging areas are consistently deburred to the same high standard. Unlike manual processes, which are prone to variations due to operator skill and fatigue, robots maintain precise movements and steady pressure over extended periods.

This allows you to achieve a flawless finish on every piece, enhancing both the aesthetic appeal and functional performance of your products. It also ensures consistent quality in large-scale production, meeting the stringent standards required in industries where precision is non-negotiable.

Maximize cost savings

By streamlining processes, robotic deburring systems significantly cut costs by enhancing efficiency, reducing waste, and minimizing rework.

Robots are programmed to remove only the necessary material, preventing over-processing and part damage. Automated tool changes further boost efficiency, reducing downtime and increasing throughput. The consistent, repeatable results delivered by robots eliminate variability and reduce the need for extensive quality checks, leading to lower labor costs and less scrap. Additionally, robots’ precise operation reduces tool wear, resulting in longer tool life and lower replacement costs.

ROBOTIC DEBURRING

Case studies for Deburring

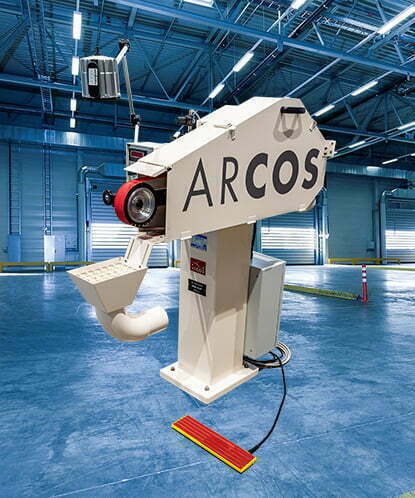

ARCOS MACHINES

Recommended Machines for Deburring

ROBOTIC DEBURRING

Types of processing

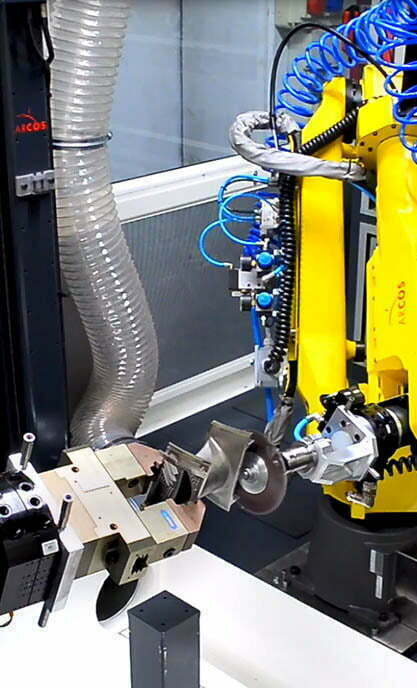

Arcos offers automated systems for robotic deburring, capable of optimizing processes and reducing cycle times, replacing manual work.

Depending on the geometrical complexity of the part and the result required by the deburring process, different deburring solutions can be applied.

Using appropriate belts, the abrasive power of the tool is applied directly to the burr.

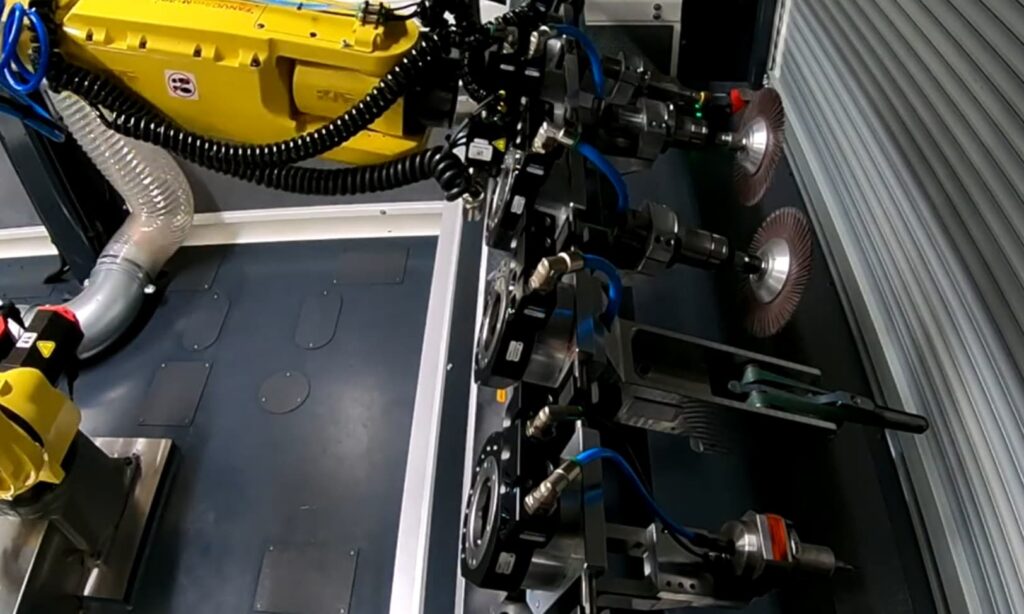

Typically used for precision deburring processes. Precision tools made of hard metal are mounted on electric or pneumatic rotating spindles. The process may sometimes require the use of several tools in different stages of deburring: in these cases, the robotic system includes an automatic tool change magazine.

ROBOTIC DEBURRING

Type of materials

Cast iron

Glass

Aluminum alloys

Brass

Zamak

Hard stones

Inconel®

Magnesium alloys

Composite materials

Plastic

Steel/Stainless steel

Titanium alloys

ROBOTIC DEBURRING

Type of objects

CONTACT US