3D printing: the evolution and advantages of its use with Arcos

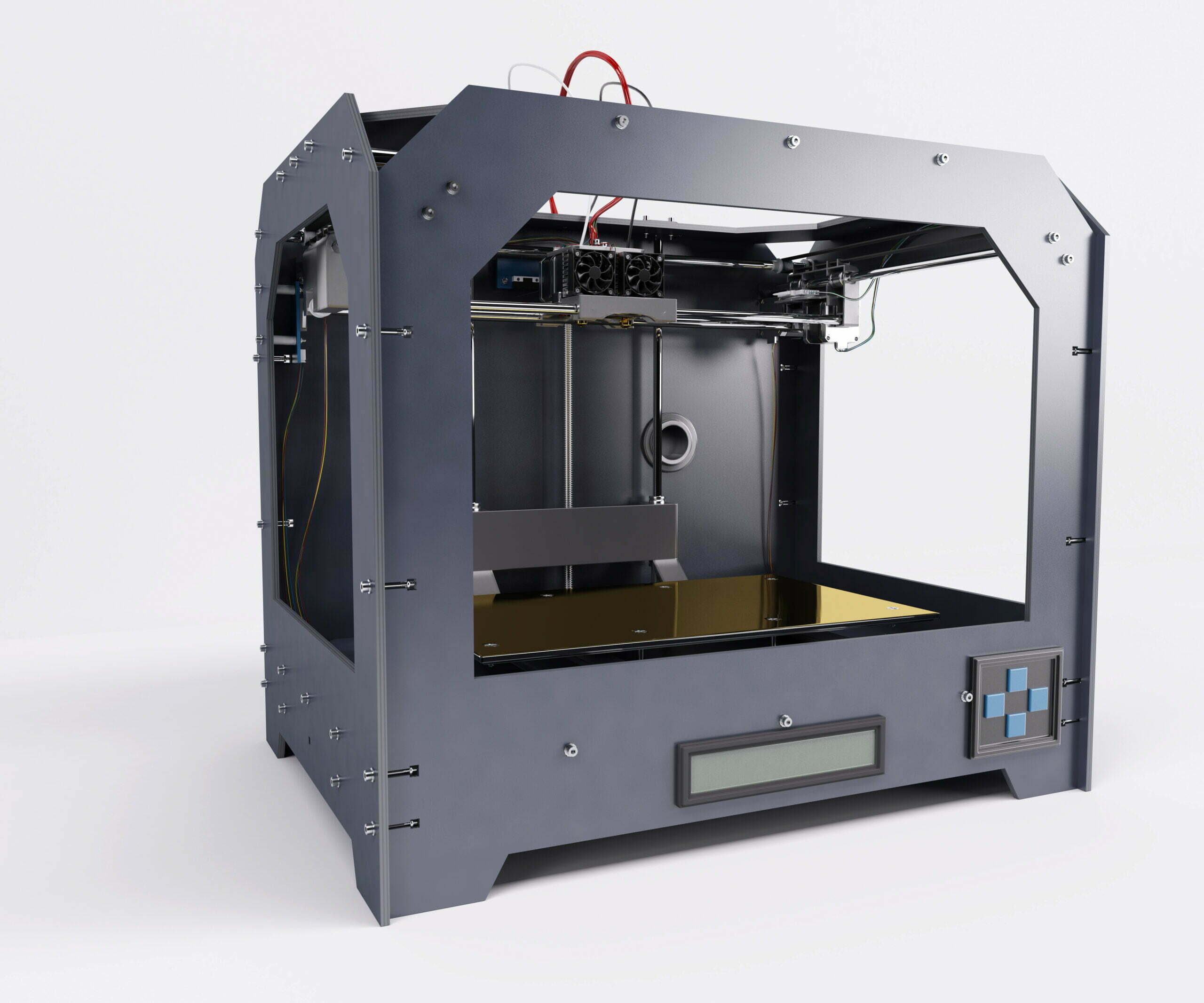

A phenomenon that is expanding more and more every day in the manufacturing world concerns additive printers. These tools lend themselves to various functions useful to companies and allow the creation of objects through digital 3D models. Let's see what the advantages of 3D printing are and how Arcos has been able to integrate it into its own reality, at the service of the growth of its customers.