Metal sanding is a crucial process for achieving smooth, uniform surfaces free from imperfections. Every company needs to polish metals for various crucial reasons that can relate to the quality, functionality, and aesthetics of the final products. Thanks to recent advancements in robotic technology, automated systems are revolutionizing this industry, bringing significant benefits in terms of costs, timing, and results.

In this article, we will explore the main tools used for metal sanding, the common types of metals that require this treatment, and how robotic systems, such as those developed by Arcos, represent the best solution for this operation.

Table of Contents

Why Metal sanding is Carried Out

What are the main reasons why metal sanding is essential in the industry? Let’s delve into the details:

- Smooth and uniform surfaces: Metal sanding allows for obtaining smooth and uniform surfaces, eliminating any roughness, scratches, slag, or irregularities present on the metal surface. This contributes to ensuring the quality of the final product and facilitates subsequent processes such as painting, plating, or assembly.

- Performance enhancement: Metal sanding can improve the performance of mechanical components and tools. By removing any imperfections or protrusions, friction and wear are reduced, promoting increased durability and reliability over time. This is particularly important in sectors such as automotive and aerospace, where precision and component strength are crucial.

- Cleanliness and hygiene: Metal sanding is often necessary to ensure the cleanliness and hygiene of certain products. For example, in the food or medical industry, metals used for equipment or packaging must be polished to remove potential areas of dirt, bacteria, or other contaminants.

- Aesthetic appearance: Metal sanding can enhance the aesthetic appearance of products, giving them a shiny finish that is free from visible defects. This is particularly important for products intended for the luxury, furniture, or decorative sectors, where aesthetics play a fundamental role in attracting customers.

- Adaptation to specific requirements: In many cases, metal sanding is necessary to adapt components or products to specific requirements. For example, in sectors such as automotive, components must be polished to adhere to precise dimensional or geometric tolerances.

In summary, metal sanding is essential for ensuring the quality, functionality, aesthetics, and compliance with specific requirements of products. It contributes to improving the performance, reliability, and durability of components, as well as meeting cleanliness and hygiene standards. Therefore, companies invest in metal sanding to ensure high-quality products that meet customer expectations and the needs of various industrial sectors.

Main Tools for Metal sanding

Metal sanding can be performed using various tools, depending on the size and characteristics of the piece being worked on. Each tool has its peculiarities and can be adapted to different processing needs.

Here is an overview of the most common tools and their main differences:

- Belt sander: It is an electric tool that uses a continuous abrasive belt to remove materials and polish the metal surface. This type of sander is suitable for working on large, flat, and regular surfaces such as tables, worktops, or sheets. It can quickly remove large amounts of material but may be less precise on complex shapes or tight corners.

- Orbital sander: It is an electric tool that uses a circular and orbital motion to polish the metal surface. This type of sander is suitable for working on curved or irregular surfaces as the orbital motion reduces the risk of concentrated sanding marks in one area. It is less aggressive than a belt sander and can be used for detailing or fine sanding.

- Grinding wheels: Grinding wheels are rotating discs with an abrasive surface. They are mounted on grinders or bench polishers and used to remove material, polish, sharpen, or buff the metal. Grinding wheels can be made of different materials such as aluminum, silicon carbide, or diamond and can have various abrasive grit sizes depending on the processing needs.

- Abrasive discs: These are similar to grinding wheels but are flat instead of rotating. They are commonly used with angle grinders or handheld polishers to sand, polish, or finish the metal. Abrasive discs can be made of various materials such as aluminum, silicon carbide, or aluminum oxide and can have different abrasive grits depending on the type of required finishing.

- Hand tools: In addition to power tools, there are also manual tools for metal sanding. These include files, rasps, sandpaper, and abrasive sponges. These tools are often used for precision work or for detailing on complex surfaces.

The choice of tools depends on the type of processing required, the size and shape of the workpiece, and the desired end result. It is important to select the appropriate tools based on the specific project needs to achieve the best results in terms of quality, precision, and productivity.

Sectors and Metals Requiring Sanding

Metal sanding is a widely used process in multiple industrial sectors such as automotive, aerospace, tool manufacturing, electronics, and many others.

The most common metals that require sanding include stainless steel, aluminum, copper, bronze, and titanium. These metals are often used in the production of mechanical components, machine parts, tools, and consumer products.

Arcos: Automated Metal sanding Systems

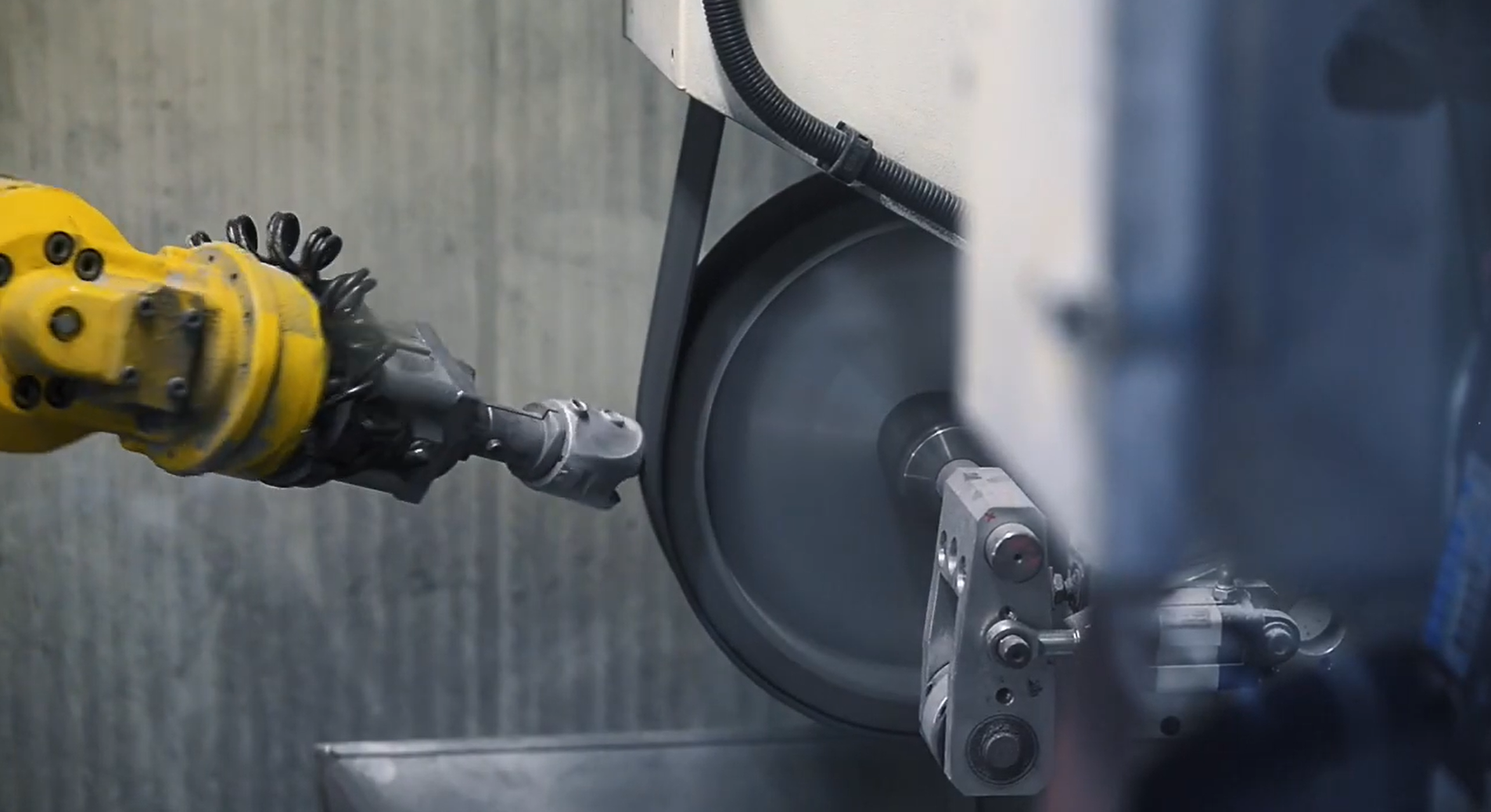

Arcos is a leading company in the development of automated metal sanding systems. With their extensive experience in the industry, Arcos can offer customized solutions that adapt to the specific needs of each customer. These automated sanding systems utilize advanced robots and intelligent software to ensure precise and high-quality sanding.

Advantages of Arcos Robotic Sanding Systems

Arcos robotic systems offer several significant advantages compared to traditional methods of metal sanding. Firstly, robots can work continuously and repetitively, ensuring precise and uniform sanding. They can perform complex tasks with great accuracy, minimizing human errors and improving the quality of the final product.

Secondly, robotic systems are extremely versatile and can be programmed to adapt to different shapes and sizes of workpieces. This allows for customizing the sanding process according to the specific needs of each production facility.

Furthermore, robotic systems reduce the risk of workplace accidents as they eliminate the need for direct interaction between operators and sanding equipment. This helps to ensure a safer work environment and reduce costs associated with injuries.

Conclusion

Metal sanding is a fundamental process for achieving smooth and uniform surfaces. The robotic systems developed by Arcos allow for efficient, precise, and safe execution of this process. This automated sanding enables companies to improve the quality of their products, increase productivity, and maintain a safe working environment.

Technological innovation is revolutionizing the metal sanding industry, so don’t miss out on the best solution for your needs. Contact us and tell us what you require, and we will find the suitable system for you.