Industry 4.0 is a concept that has been revolutionising industrial sectors around the world for a few years now, introducing a new production paradigm based on automation, interconnection and the use of data.

Within this article, we are going to understand what is meant specifically by the term ‘Industry 4.0’, as well as what are the incentives for the transition to this new production model, the requirements of a 4.0 machine, and the fundamental contribution offered by Arcos to guide companies through this transformation.

Table of Contents

What is meant by Industry 4.0?

Industry 4.0 represents the fourth industrial revolution, which is mainly characterised by the total integration of physical and digital production systems.

This means that companies have started using highly automated machinery and systems that can communicate with each other and that are equipped with a central system to improve the efficiency, quality and flexibility of production. All this translates into intelligent machinery capable of self-optimisation.

What are the incentives for the transition to Industry 4.0?

The transition to Industry 4.0 is encouraged by various incentives at government level. These incentives vary from country to country, but usually include tax breaks, financing, tax credits and training support programmes. The main objectives of these incentives are to stimulate the adoption of advanced technologies and to improve the competitiveness of domestic industry.

In Italy, the Budget Law 2023 (Law No. 197/2022) confirmed the current legislature’s commitment to supporting the Transition 4.0 Plan by refinancing a series of measures. These measures, aimed at facilitating the technological and digital transition of companies, have been extended until 31 December 2025 and, in some cases, until 30 June 2026.

Among these measures, the tax credit for investments in capital goods is the main incentive instrument. The rate from 2023 to 2025 for tangible capital goods 4.0 is 20% for investments up to EUR 2.5 million, 10% for investments between EUR 2.5 and 10 million and 5% for investments between EUR 10 and 20 million. For intangible capital goods 4.0, on the other hand, the rate is 15% for investments up to EUR 1 million for 2024, and 10% for investments up to EUR 1 million for 2025.

What are the requirements for incentives?

To be eligible for Industry 4.0-related incentives and, in particular, the Transition 4.0 tax credit, companies must meet certain requirements, including:

- Timing of acquisition: in order to qualify for the tax credit, it is essential that the order for the acquisition of the capital goods has been accepted by the seller within the reference year. In addition, payment of at least 20% of the acquisition cost within certain deadlines is required.

- Investment in technology: companies have to prove that they have invested in advanced machinery and technologies that support Industry 4.0.

- Strategic planning: a strategic plan showing how the company intends to implement Industry 4.0 and what benefits it expects to achieve is often required.

- Staff training: employee training is often a requirement, as it is crucial to have qualified staff to handle new technologies.

- Compliance with regulations: companies must comply with national and international regulations and standards on security and data protection.

- Timing: the deadlines for accessing the tax credit vary depending on the year of investment, with different periods of application of the benefits until 2026.

What makes a machine a 4.0 capital good?

A machine can be considered a 4.0 capital good when it meets the following requirements:

- Connectivity: the machine is able to connect to a network or communication system, enabling real-time data transmission between the machine itself, other machines and company systems.

- Sensors and monitoring: it is equipped with sensors that detect data on its performance, operating status and surrounding environmental conditions.

- Advanced automation: the machinery is able to perform tasks autonomously or semi-autonomously, adapting to conditions in real time without constant supervision.

- Process digitisation: contributes to the digitisation of production processes, enabling the creation of a ‘smart factory’ where processes are digitally monitored and managed.

- Safety: is designed with advanced safety features to prevent accidents and protect workers.

- Energy efficiency: it is designed to be more energy efficient, reducing operating costs.

Arcos’s contribution to the transition to Industry 4.0

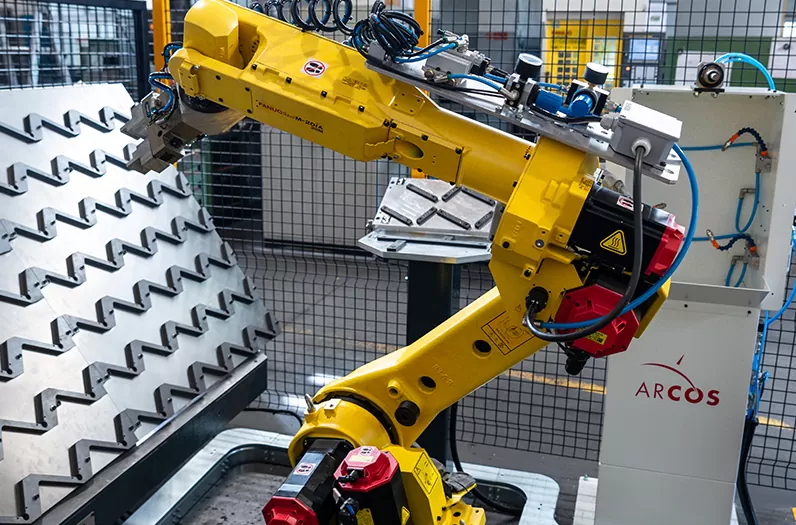

Arcos is a leading manufacturer of robotic systems for Industry 4.0. Thanks to the vast experience accumulated since its inception, our team is able to offer companies a complete range of machinery and services to support the transition to Industry 4.0.

The services offered by Arcos include:

- Consulting: we provide customised consulting to help companies identify the best solutions for their specific needs.

- Provision of advanced machinery: we offer a wide range of intelligent, connected machinery designed to improve production efficiency and quality.

- Training: we offer training programmes to ensure that company personnel are adequately prepared to handle new technologies.

- Technical support: we provide continuous technical support to ensure that the machinery functions properly.

Conclusion

Industry 4.0 represents a significant turning point in industry, offering great opportunities to improve efficiency and competitiveness. Government incentives make this transition even more attractive for companies, and with the support of experts like Arcos, you can tackle this challenge effectively and successfully. Contact us!