Robotic Cells

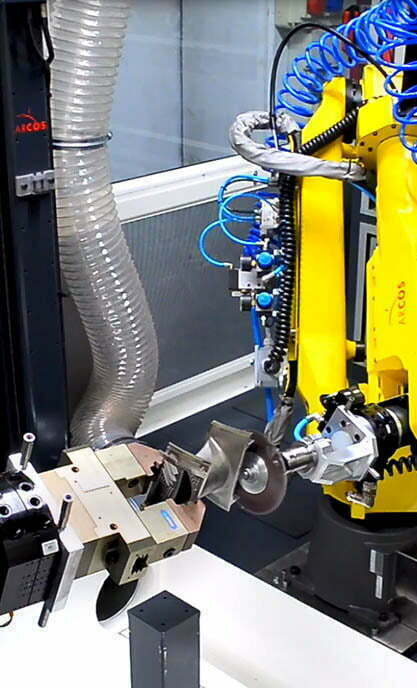

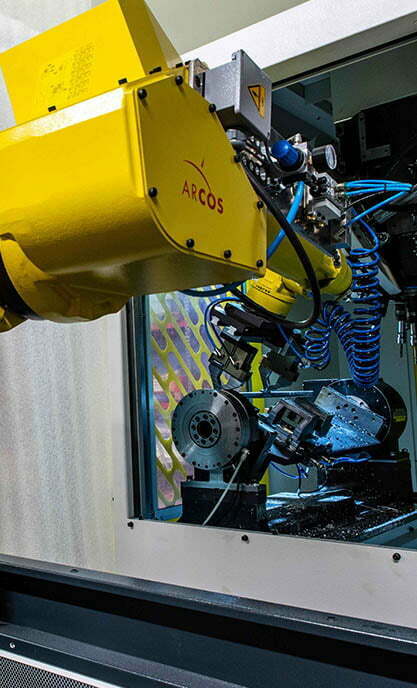

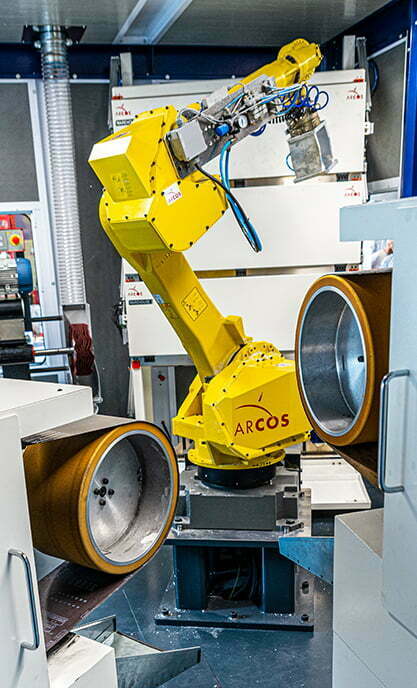

Arcos develops and implements automatic finishing systems with the use of robots and cutting-edge technologies. Arcos robotic cells guarantee great reliability and flexibility: their technology, in fact, guarantees the highest level of performance for multiple and diversified processes (from the handling of objects, assembly, quality control, sorting, painting, etc.).

All robotic finishing systems are designed and built to meet the production needs of the customer, for this reason one of their strengths is the possibility of including a fully customized robotic cell in your production system. The close collaboration with Arcos engineers and designers, in sharing with the customer’s ideas, allows us to create highly customized robotic cells integrated with the customer’s production reality.

Arcos robotic cells are able to work pieces of any material even with very complex geometries; therefore, they are able to satisfy requests from various sectors such as Aeronautics, Automotive, Energy, Oil and Gas, Medical, Weapons, Watchmaking, Luxury and Fashion, Furniture and much more.

Replacing manual work with Arcos robotic systems is the winning choice if you have high productivity or if manual work is risky or unrewarding. The benefits obtained with these autonomous tools are manifold: production rates increase considerably, the possibility of error decreases and operators can perform more satisfying and less dangerous tasks.

Each robotized cell designed by Arcos is built with the best safety systems. In fact, each system has soundproofed and aspirated protection cabins, while the supervision of the work of the machine is entrusted to the HMI – Human Machine Interface system.

ROBOTIC CELLS

Features

Arcos robotic systems provide the best cutting-edge technology by offering:

ROBOTIC CELLS

CASE STUDIES FOR ROBOTIC CELLS

CONTACT US