Within the manufacturing industry, the choice of metalworking machines plays a crucial role in ensuring precision and efficiency in production processes.

In this article, we provide a detailed mini-guide to help you select the most suitable machine for each stage of metalworking, exploring the solutions offered by Arcos.

Table of Contents

Each metal has its own processing

Each metal, depending on its composition, requires a specific approach in machining to achieve optimum results.

Choosing machines and working methods capable of effectively handling physical and chemical properties is essential to achieve superior finishes on each type of metal.

The metals taken into consideration are:

- Steel and stainless steel: suitable for grinding, polishing and laser cutting, they maintain high quality standards;

- Aluminium: ideal for satin-finishing and plasma cutting. Both processes ensure the protection of the delicate surface;

- Titanium and light alloys: for automatic sandblasting processes that remove impurities without compromising the strength of the material.

Metalworking Machines: what to choose?

Arcos offers specialised machines for a wide range of metalworking applications, each designed to meet the specific requirements of different production processes.

Let’s start with deburring: our machines use advanced technology for precise metal burr removal, which is crucial to ensure the highest quality in industrial applications.

Next, we move on to grinding: which ensures uniform, smooth surfaces and is ideal for applications requiring high standards of precision and finish, essential in industries such as aeronautics and precision equipment manufacturing.

In the field of polishing and brightening, we offer advanced solutions to improve the brilliance of metal surfaces, perfectly meeting the aesthetic and functional requirements of the most demanding manufacturing industries.

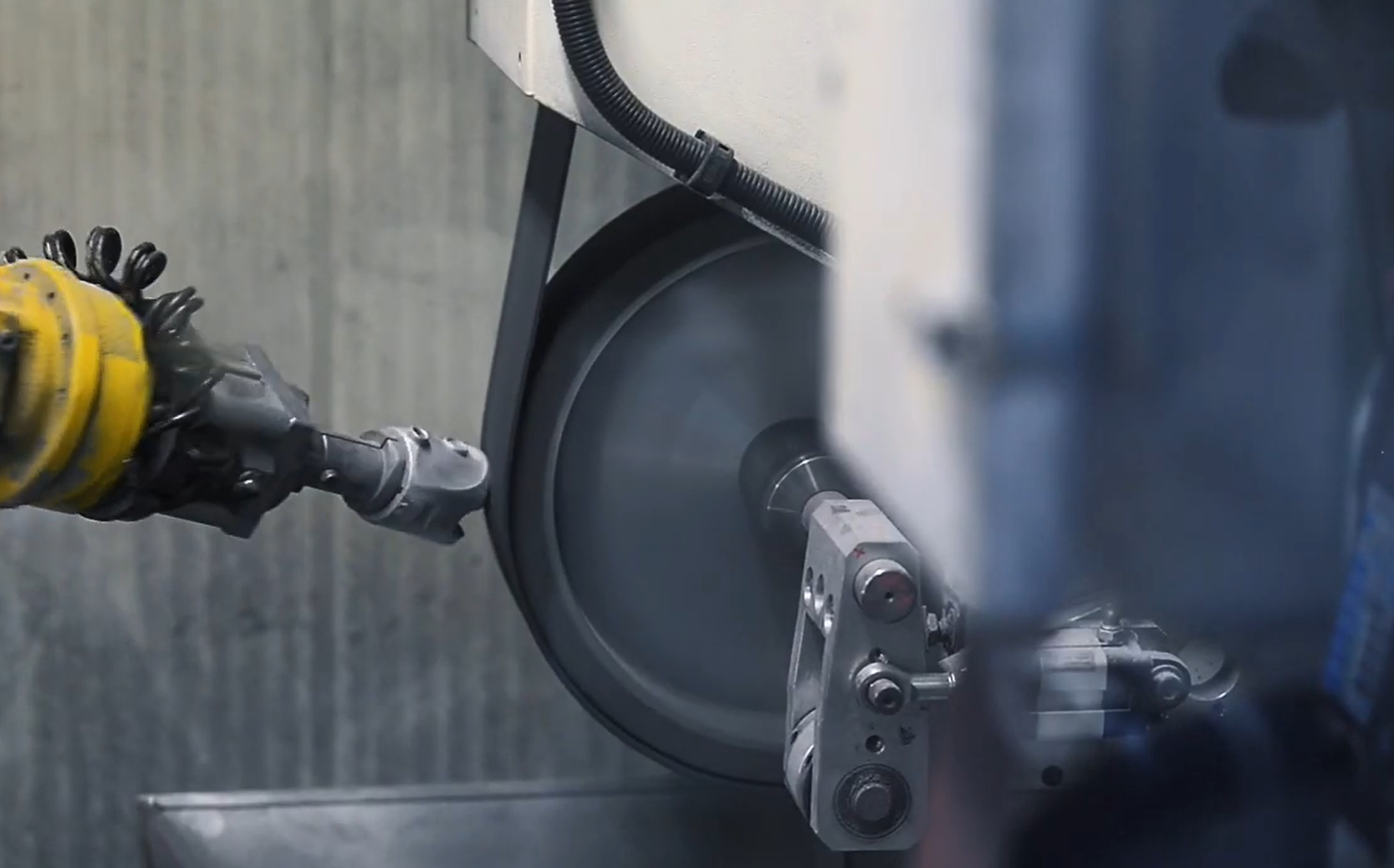

In addition to more traditional processes, we also offer highly specialised machines such as automatic sandblasting: robotic systems that effectively remove surface contamination, preparing the metal for subsequent treatments with a precision and consistency that is difficult to achieve with traditional methods.

Our satin-finishing machines create matt and silky surfaces, reducing light reflection and greatly enhancing the aesthetics of the finished product.

Finally, laser and plasma cutting technologies represent the pinnacle of innovation in the precise cutting of metallic materials, essential for the production of complex and detailed components used in a wide range of industrial applications, such as aeronautics and the energy industry.

Two Arcos case studies

The robotic system for satin-finishing electrical enclosures is a specialised technology that guarantees uniform, high-quality satin-finishing.

In addition, we offer the robot system for sandblasting aerospace components as a solution for the demanding requirements of the aerospace industry.

In conclusion

Choosing the right machines for metalworking is not just a question of advanced technology, but represents a strategic investment in improving production efficiency and quality.

Arcos stands out for the innovation and reliability of its solutions, supporting companies in their quest for excellence and market competitiveness.

To find out how Arcos machines can revolutionize your production, contact our team today.