Metal brushing, once considered exclusively a manual and artisan craft, has undergone a remarkable transformation thanks to the technological revolutions of the modern era. This evolution has turned a traditional technique into a sophisticated process where precision meets innovation. Today, the integration of advanced technologies and robotics has not only improved the quality of the finish but has also opened new possibilities in terms of design and functionality.

In this article, we will discover the most effective and advanced tools for this process, considering the critical factors that every company should evaluate in choosing the most suitable equipment.

Table of Contents

How does this process work and what benefits does it bring?

Metal brushing is an industrial process used to improve the aesthetic appearance and surface quality of metals. This process can remove imperfections, create a uniform finish, and prepare the metal for further treatments such as painting or welding.

Here is how this process generally works:

- Metal preparation: before starting the brushing, the metal is usually cleaned to remove any oil, grease, or dirt that might interfere with the finish. The surface can also be smoothed to remove rust or other imperfections.

- Selection of the brushing tool: a suitable brush is chosen based on the type of metal and the desired finish. Brushes can vary in terms of material, density, and stiffness of the bristles.

- Brushing process: the metal is then treated with the brush. This can be done manually or, more commonly, with automatic or semi-automatic machines. During the process, the brush is moved over the metal surface in a controlled manner. The pressure, speed, and angle of contact of the brush are adjusted to achieve the desired finish.

- Finish control: during and after the brushing process, the metal’s finish is examined to ensure it is uniform and meets the required specifications. This control can be done visually or with specific measuring instruments.

- Post-processing cleaning: after brushing, the metal surface is cleaned to remove any metal residue or dust produced during the process.

- Additional finishes: if necessary, the metal can undergo further post-brushing treatments, such as the application of paints or protective coatings.

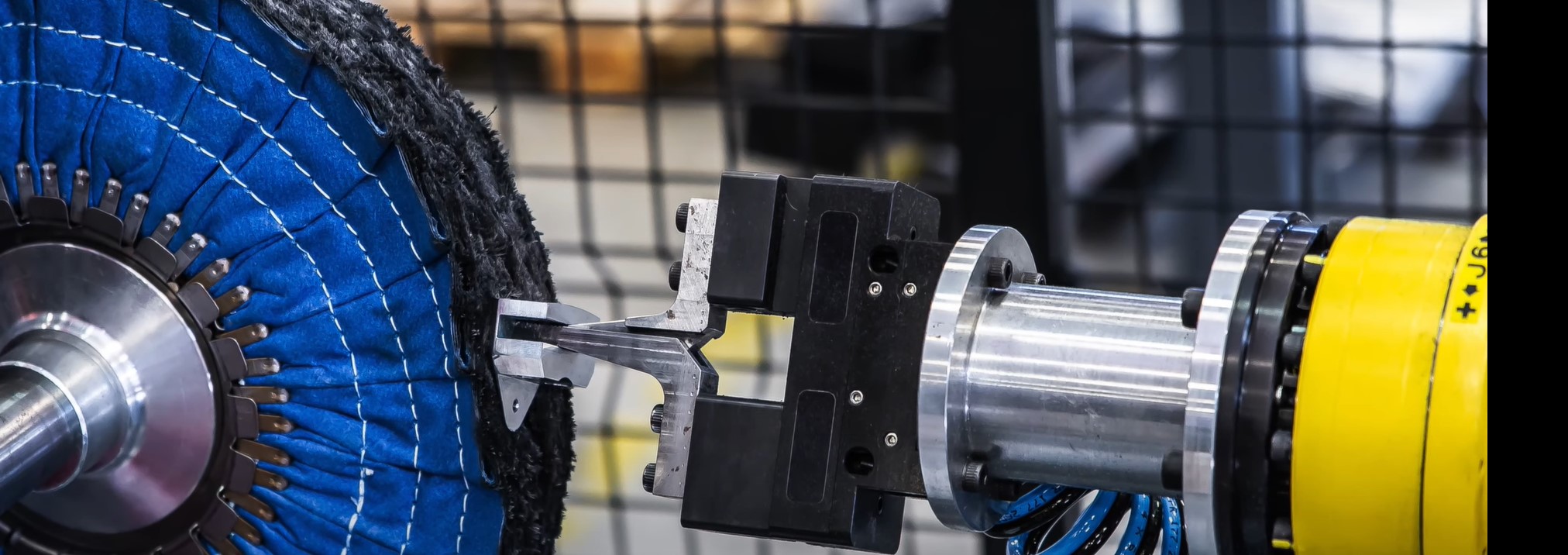

In modern industrial applications, the brushing process is often automated using computer-controlled machines and industrial robots. These advanced automation systems offer greater precision, consistency, and efficiency, allowing high-quality brushing on a large scale. The solutions from Arcos, in particular, with their advanced technology, are excellent examples of how robotics can optimize and improve the metal brushing process.

Ideal tools for metal brushing: versatility and effectiveness

Choosing the right tools for metal brushing is crucial to achieve a high-quality finish. The best tools stand out for their ability to adapt to different types of metals while ensuring efficiency and precision. Here are some of the most effective tools for metal brushing and the reasons for their superiority:

- Rotating stainless steel brushes: ideal for working with stainless steel and other hard metals. The stainless steel bristles resist wear and maintain their stiffness, ensuring a uniform and lasting finish.

- Brushes made of synthetic abrasive materials, such as nylon impregnated with abrasives, are perfect for softer metals like aluminum. These brushes effectively remove surface imperfections without causing scratches or other damage.

- Belt brushes: particularly effective for finishing flat surfaces. Their structure allows for uniform pressure, resulting in a smooth and homogeneous finish.

- Robotic brushing units: the robotic tools offered by companies like Arcos represent the frontier of innovation in this field. These automated systems allow precise control of pressure and speed, ensuring high-quality finishing on large production volumes. Robotization also reduces the risk of human errors and increases the consistency of the final result.

- Programmable control systems: allow precise adaptation of the brushing to different types of metals and desired finishes. This flexibility is essential for achieving optimal results across a wide range of applications.

The choice of the right tool depends on the specific goal of the processing, the type of metal, and the desired finish.

Critical considerations in choosing the equipment

Every company must consider several key factors in choosing equipment for metal brushing:

- Type of metal: different metals have unique characteristics and therefore require different types of brushes to avoid surface damage. Let’s give some examples:

- for stainless steel, soft wire or non-ferrous material brushes, like aluminum, are often used to prevent contamination and preserve the shiny finish.

- aluminum, being softer, requires brushes with softer bristles or synthetic material to avoid scratches and surface damage.

- copper and bronze alloys favor fine wire brushes to maintain a smooth surface and preserve their characteristic color and shine.

- Desired finish: the grain of the brush directly affects the finish. A finer grain is ideal for more delicate finishes.

- Durability and maintenance: tools should be durable and easy to maintain to ensure a long lifespan.

- Automation and control: automatic systems with precise controls can improve the efficiency and quality of the process.

Conclusion

Metal brushing is a complex process that requires attention, precision, and the right tools. The importance of this process in improving the aesthetics and quality of metal surfaces is invaluable, finding applications in numerous industrial sectors, from automotive to aerospace, from equipment construction to consumer goods.

Choosing Arcos as a partner in this process ensures not only quality and efficiency but also innovation and safety. With Arcos’ customized and technologically advanced solutions, companies can reach new levels of excellence in finishing their metal products.

Contact us here for more information on the automated solution useful for brushing your metals.